Geomagic Control X

Powerful, Accurate, and Easy-to-Use 3D Metrology Software

Geomagic Control X

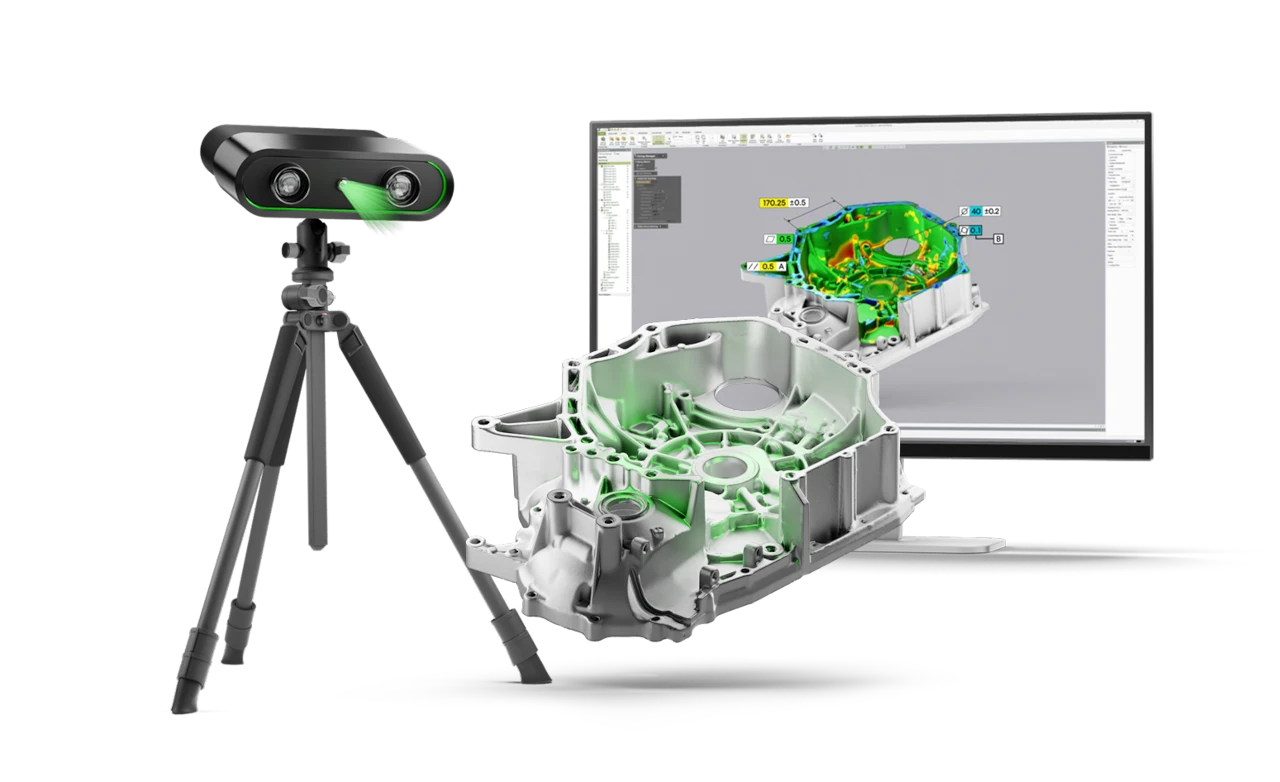

In today’s world of engineering and manufacturing, every millimeter counts. Geomagic Control X is 3D metrology software designed to offer precision, traceability, and ease of use in every inspection process. From automated production lines to quality control laboratories, this program adapts to any environment and measuring device.

With Geomagic Control X, you can measure, understand, and communicate your inspection results with complete confidence, improving the quality of your products and optimizing analysis time.

A Tool that Adapts to Your Workflow

One of the greatest advantages of Geomagic Control X is its universal compatibility. It works seamlessly with virtually any 3D scanner or measurement device, from the most advanced optical scanners to portable probing systems.

This means it doesn’t matter if you work with equipment from Creaform, Artec, Zeiss, or FARO: the integration is fluid, with no unnecessary learning curve.

Features that Make the Difference

Compare Scans with CAD Models

Visualize deviations in seconds with intuitive color maps that show which areas are inside or outside tolerance. You can perform 3D comparisons, 2D sections, analysis by curves, boundaries, or silhouettes. Furthermore, it integrates with the main CAD systems on the market, such as SolidWorks, Siemens NX, or CATIA.

Smart and Flexible Alignment

Geomagic Control X offers multiple alignment methods: automatic, feature-based, RPS, Datum, or 3-2-1. Everything depends on your need. If you are inspecting complex parts, you will be able to align precisely without wasting time on manual configurations.

Analyze Surface Wear or Deformation

Ideal for industrial maintenance or mold control. It detects even micro-deformations on metal or plastic surfaces, comparing scans over time. Perfect for evaluating wear in turbines, tools, or friction-prone components.

Combine 3D Scanning with Tactile Probing

Do you use a scanner and a measuring arm? Geomagic Control X unites both worlds in the same interface. This way, you can inspect both visible and internal areas without changing software or duplicating work.

Rapid Measurement and Automatic Dimensioning

With just a few clicks, the system recognizes basic geometries and generates precise measurements. It supports 2D and 3D dimensioning with tolerances according to ASME Y14.5M, including straightness, flatness, concentricity, and total runout.

Visual Reports and Seamless Collaboration

Creating inspection reports has never been easier. Geomagic Control X allows you to generate interactive 3D reports that can be opened on any PC or mobile device without additional software. You can customize templates, compare historical results, or share them in PDF format with dynamic views.

For example, in a quality control laboratory, you can send your colleagues a report where they can rotate the 3D model, view deviations, and instantly understand what needs to be corrected.

A tool that brings technical data closer to the entire team, even those who are not metrology experts.

Power, Automation, and Python at the Service of Metrology

For industrial or continuous production environments, Geomagic Control X takes automation to the next level.

It allows you to create visual workflows without the need for programming, dragging and dropping operations in an intuitive environment.

And if you are more advanced, you can use Python to develop customized scripts, integrate AI, or connect the system with databases and production lines.

With the Automation Server, it is possible to execute inspections in parallel on multiple devices, automatically sending the results (pass/fail) to external production or ERP systems.

Real-World Use Cases

- Automotive and Motorcycles: Validation of chassis, molds, and metal panels.

- Aerospace: Analysis of aerodynamic profiles, blades, and blisks.

- Education and Technical Training: Universities and metrology centers that teach dimensional control.

- Dentistry and Medicine: Control of prosthetics, implants, and anatomical models.

- Art and Heritage: Digitization and inspection of sculptures, engravings, or historical pieces.

Available Plans

Essentials

Ideal for small businesses or workshops that need a reliable and affordable 3D inspection solution.

Essentials Connect

Includes advanced connectivity for CMM arms and portable scanners, ideal for metrology labs or production control.

Professional

Full version for advanced industrial environments, with automation, scripting, and batch control.Professional Full version for advanced industrial environments, with automation, scripting, and batch control.

Why Choose Geomagic Control X?

- Reduces inspection times by up to 60%

- Integrates with over 50 brands of 3D scanners

- Generates clear, visual, and easy-to-share reports

- Facilitates collaboration between engineering, production, and quality

- Guarantees precision, traceability, and reliability in every measurement

Want to see how Geomagic Control X can improve your inspection process?

Use 3D Tools for 3D Tasks

Haptic Devices

For great freedom of expression and faster modeling, Geomagic Freeform products work exclusively with 3D Systems’ Touch haptic devices to provide the physical sensation of sculpting in a virtual environment. This more intuitive way of interacting with your 3D designs reduces the learning curve, speeds up the design process, and allows for the delivery of excellent quality 3D data.

Capture physical objects in 3D directly in Freeform with the Geomagic® Capture™ 3D scanner, the most powerful and integrated industrial 3D scanner and software. Bring the real world into the digital one and make use of existing shapes and your own creations. Add complex design elements and create creative models with scanned components.

Geomagic Control X: powerful metrology software for exceptional quality! Optimize your inspection process! Contact us for more details.