In the changing world of manufacturing and design, at Improto 3D, we are committed to putting innovation in your hands. We integrate cutting-edge technological tools, experience, and solid engineering to bring your ideas to life. Discover how our passion for excellence in 3D printing redefines the way you create. From the popular FDM to the precise SLA, we offer you state-of-the-art solutions to turn your concepts into tangible reality.

Pricing: Charged per printing time and material used; quoted upon request.

What is 3D printing?

3D printing, also known as additive manufacturing, is a group of manufacturing technologies that build three-dimensional objects by successively stacking layers of material.

A 3D printer reads the digital designs of an object and then converts them into real physical objects by depositing thin layers of plastic, metal, ceramic, or other materials. This additive manufacturing method allows for the creation of objects with complex shapes that would otherwise be difficult or impossible to produce with traditional manufacturing methods.

3D printing is transforming the way products are designed and manufactured across many industries.

Tips for designing a 3D model

- Start with a hand sketch or drawing of what you want to model. This will help you visualize the design.

- Use CAD (computer-aided design) software like Fusion 360, Blender, or SketchUp to create the digital 3D model. These programs allow you to model solids and surfaces in 3D.

- Start with simple basic shapes like cubes, cylinders, or spheres and gradually add details. Use operations like extrusion, cutting, or filleting to shape the model.

- Ensure the model is a closed solid and has no gaps. Check that there are no overlapping faces or edges.

- Maintain a minimum wall thickness and avoid fragile supports or parts that extend too far into the air.

- Export the model to a standard format for 3D printing, such as STL, OBJ, or 3MF. Perform a final review before sending it to print.

If you need advice with your 3D design or wish to digitize or scan an object for future 3D printing, we can help you with that. Write to us on our WhatsApp 3006198934 for personalized advice.

How to submit the model for 3D printing?

The 3D model must be exported in a standard format for 3D printing, generally STL, OBJ, or 3MF. Then you send the digital file to our email info@improto3d.com for viewing, quoting, and printing. You can also bring the model on a USB drive to our facilities in Medellín.

If you need help with the process, you can contact us on our WhatsApp 3006198934

Gallery of some 3D printed parts

Need help?

Contact us

Error: Contact form not found.

FDM and SLA 3D Printing Techniques

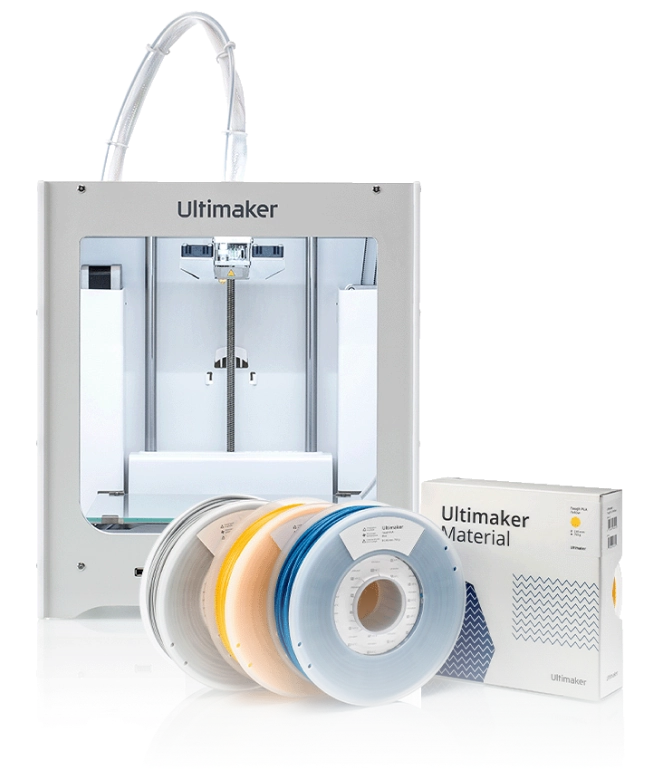

3D printing has become more accessible to hobbyists and professionals thanks to the development of technologies like Fused Deposition Modeling (FDM) and Stereolithography (SLA). While FDM is the most common and economical consumer option, SLA offers greater precision and versatility.

FDM 3D Printing

FDM (or FFF) printing is the most common form of consumer 3D printing. It uses a plastic filament that is heated and extruded to build objects layer by layer. FDM printers can use various types of plastics such as ABS, PLA, and blends. It is suitable for basic models, rapid prototyping, and low-cost simple parts.

Stereolithography 3D (SLA)

Stereolithography (SLA) was the first 3D printing technology. It uses a UV laser to cure liquid resin and turn it into plastic, in a process called photopolymerization. It builds objects layer by layer, curing each cross-section with the laser. SLA offers the highest resolution and precision, the sharpest details, and the best surface finish of 3D printers. The versatility of photopolymer resin materials allows them to match properties of standard thermoplastics.

It is excellent for high-detail prototypes, molds, patterns, and functional parts that require tight tolerance and smooth surfaces. It is used in engineering, product design, manufacturing, dentistry, jewelry, models, and education.

Ready to bring your ideas to life? Discover how 3D printing can boost your creativity and take your projects to the next level.

Frequently Asked Questions about 3D Printing in Colombia

At Improto 3D, we are your best option for 3D printing. With cutting-edge technology and an expert team, we transform your ideas into tangible reality. Contact us now and discover the magic of 3D printing!

3D printing time varies depending on the size and complexity of the object. However, with our efficient technology and optimized processes, we guarantee fast turnaround times so you can get your creations quickly.

The 3D printing process begins with the creation of a digital model of the object you wish to print. That model is then sent to our 3D printer, where it is printed layer by layer using high-quality materials. Once the print is complete, the object is ready to be used or painted according to your needs. Let us bring your ideas to life with our efficient and precise 3D printing process!

3D prints can be made with various materials, from plastics like PLA and ABS to resins, metals, and even ceramics. The choice depends on the intended use and application.

3D printing is an additive manufacturing process that builds objects layer by layer from a digital model. It uses technologies like FDM or SLA to create three-dimensional parts.

3D printing is a revolutionary technology that allows for the creation of three-dimensional objects from digital models. It is a versatile tool used across various industries for prototyping, production, and more.

3D printing is used in a wide range of applications, from rapid prototyping and production of customized parts to dentistry, medicine, industrial design, architecture, and more. It is key for creating prototypes, unique parts, and small-scale production.

3D printing works through a process called additive manufacturing, building objects layer by layer from a digital model. It uses technologies like FDM or SLA that melt or solidify materials to create three-dimensional objects. The process begins with designing the model in software, then the 3D printer follows instructions to deposit material layer by layer, thus creating the desired object.